Title: Different mindsets about stubble burning on display from the same farming region in India

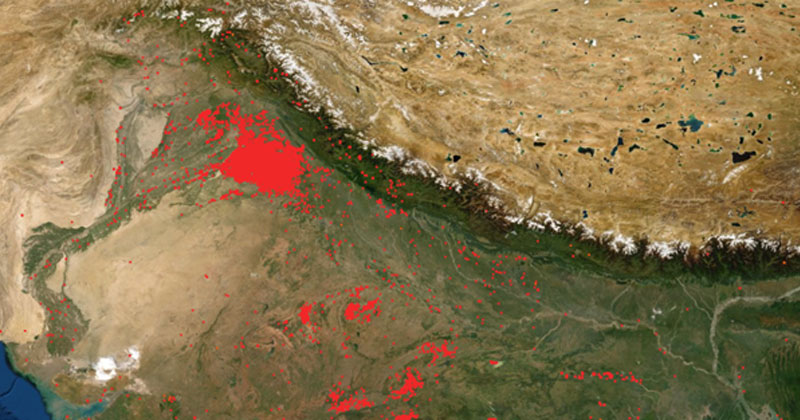

The issue of air pollution in Delhi has been making the headlines continuously for the better part of this decade. Air Visual, the agency which monitors international air pollution, has ranked New Delhi as the most polluted capital in the world- this despite the government’s push to decrease the pollution levels in the city. The situation is exacerbated in the winter months when various factors such as low wind speed, vehicular emissions, and crop stubble burning combine. As per sectoral studies done recently, the overall average coarse particulate matter concentration of PM2.5 levels go up from 300 µg/m3 in summer to 375 µg/m3 in winter against the acceptable level of 60 µg/m3. A study by ‘The Energy and Resources Institute’ has also indicated that the open burning of agricultural residue in rural areas contributes about 7% to the total PM2.5 emissions. The enhanced concentration of particulate matter in October to November can be attributed to crop residue burning in Punjab, Haryana, Uttar Pradesh, and Rajasthan.

Are There Viable Green Alternatives?

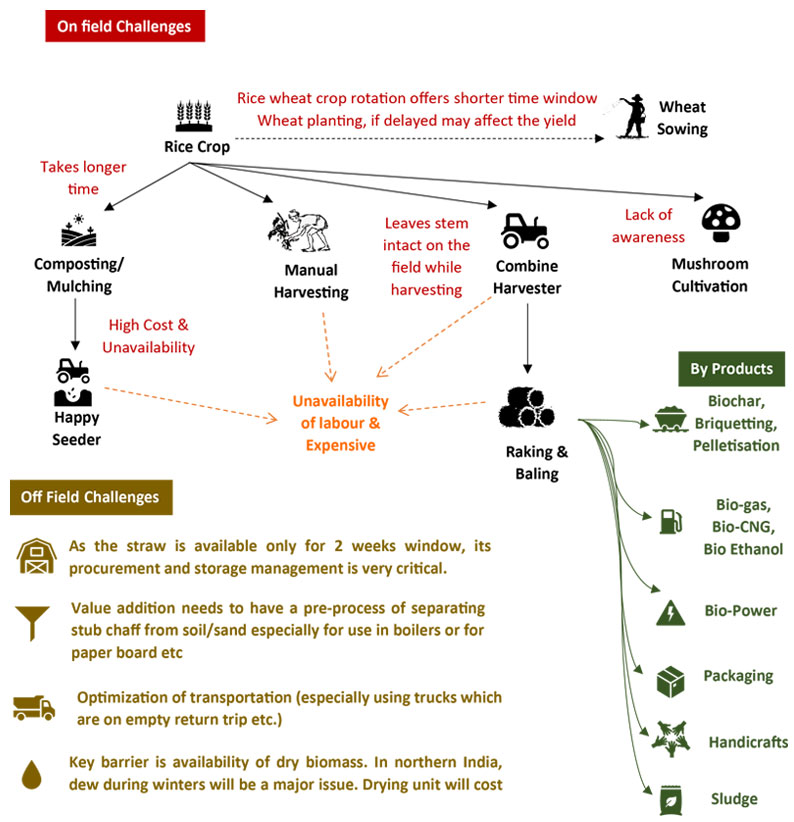

The rapid introduction of combine harvesters was a game-changer practice for rice growers in the North, as the machine combines the fields, they spread rice straw, giving the farmers option to collect the bi-product. The manual collection is unprofitable because of the high labour cost. Incorporation in the soil also seems an unviable option in current agri-systems with two to three crops per year because the turnaround time is too short for decomposition. These constraints lead to farmers burning the rice straw directly in the field, causing high unwanted emissions which lead to widespread health problems. But with the development of recent technologies, rice residues can be processed and managed with better practices. Scalable processing and management options of rice straw can be classified as in-field and off-field options. Below are some of the industrial use cases for rice straw, which if promoted – can provide farmers an alternative avenue to direct the burning of stubbles in the fields.

1. Packaging

Using paddy straw for packaging purposes will not only resolve the problem of management of paddy straw but also help in reducing the plastic use for packaging. Using chemical pulping technology rice straw can be converted into paper and cardboard for packaging. The straw can be incorporated with wood chips in making fiberboard. This increases the economic status of farmers along with environmental benefits.

2. Biochar

Paddy straw can be converted to Biochar which is equivalent to activated carbon by pyrolysis in a brick kiln that can be designated at the site. This biochar is used to make renewable intense sticks, de-odorizer, garden fertilizer, etc. It also enhances carbon content in the soil and is used for bioremediation of degraded soils.

3. Briquetting

Biomass can be transformed into briquettes of regular shape which are easier to use, convenient to transport and store. Although the low calorific value of paddy straw compared to other crop residue is a challenge, briquettes have a good potential of being co-fired into industrial boilers along with coal and other high calorific crop residues. These can be used as fuel in gasification furnaces, heaters, hot water boilers, and industrial boilers. It is a very good substitute for furnace oil, coal, or direct wood. The key enabler is proper recognition for industry and those using briquettes. The rice straw holds potential as an alternative to coal in thermal power plants. Offering green certifications and rewarding them based on the quantity of briquettes used may attract more players to this sector.

4. Pelletisation

Pellet is compressed biomass which is 20-40 mm long tablets with 6-8 mm diameter. These pellets find application as fuel in cooking stoves heating applications in the domestic sector as well as industries. It could be a good substitute for coal or direct wood when used in a properly designed cookstove for the purpose. It has a huge potential to be used in mass cooking operations like schools providing midday meals, mega kitchens, social places like Gurudwaras, etc.

5. BioCNG

The shredded paddy straw on digestion produces biogas which can be further purified and compressed to produce BioCNG. BioCNG finds its application in HoReCa Segment, Industrial Segment, and Automotive sector. The sludge which is a byproduct of the production process can be dried and sold as manure.

6. Liquid fuels from Biomass

Conversion of biomass to liquid fuels is in its nascent stage and the technology is currently being explored in India by a few private players. One of the technologies used to convert biomass is through a continuous catalytic thermo-chemical process which produces cost-effective fungible hydrocarbon transportation fuels from the agricultural, forest, and sorted municipal residues. The petrol and diesel produced through this method will conform to Bharat VI norms and can be used directly in cars, trucks, engines, etc. Monetize urban/rural wastes (assigns an economic value to wastes). Reduce overall dependence on imported energy. Reduce carbon footprint.

7. Dry fermentation biogas plant for anaerobic digestion of paddy straw

Dry fermentation biogas plant for anaerobic digestion of paddy straw is a government-approved process. Paddy can be utilized as an energy source (biogas) by anaerobic digestion of paddy straw through the Dry Fermentation batch process. Depending on the plant capacity, once the digester is loaded and activated, it would produce sufficient gas for 3-4 months. The digested material produced from the plant is good quality manure and can be disposed of easily. The gas production is in the range of 4-5 m3/day for 3-4 months which is equivalent to 3-4 cylinders of LPG per month. The Punjab Agriculture University has 5 such biogas plants successfully running. These gas plants can be installed in areas near villages to be able to provide biogas to the local community. The households in a village which are using wood/other fuel can be made to switch to biogas.

8. Bioethanol

Ethanol production from paddy–straw using advanced biofuel technology could pave the way in the future for second-generation biofuels derived from crop-residues. It can have a double effect in tackling air pollution in rural and as well as urban areas by achieving cleaner transport fuels through blending biofuels. Bio-CNG and biofertilizers are two co-products of the bio-ethanol plant. One of the plants is already under operation in Punjab and government is in the process of setting up a few more plants in the region in collaboration with OMCs to meet the targets for ethanol blending.

9. BioPower

Energy from paddy straw can be harnessed in a biopower plant. Punjab has already taken the initiative in setting up plants. With the establishment of more such waste to power plants, stubbles will not be burned and will be recycled and used to generate electricity. The by-products include ash, which can be used in the construction of roads.

10. Composting

Compost is produced based on the mixing of rice straw, animal manure, and enzymes using the turner and ensilage to optimize the composting process. The compost product can be used as a medium for growing vegetables and other crops or spread on the rice field as a soil amendment. It enhances nutrients (i.e., nitrogen and carbon contents) and the organic matter content of the soil.

Coal is used in 9000/hotels/restaurants in the city of Delhi which use coal in Tandoor. 10% of city households use coal for cooking.

11. Mushrooms Cultivation

Mushrooms, by their nature, can break down organic material that other microorganisms cannot decompose. Many types of mushrooms grow well on compost that comes from rice straw. Farmers can generate income from mushroom production as they don’t need expensive inputs and will be ready for harvest in 20-25 days. Furthermore, the organic matter that remains after collecting the mushrooms can be used as fertilizer on farmers’ fields.

Having different management options for rice straw will provide opportunities for livelihood and business opportunities for rice value chain actors. Having sustainable options also increases energy efficiency and enhances economic benefits.

Why Do Farmers Burn Stubble?

It is imperative to understand the reasons why a problem exists before attempts are made to solve it, so a look at the underlying factors of why farmers undertake stubble burning must be taken. Niti Aayog’s report on Biomass Management has reported that every year, approximately 30 Million Tonnes of rice is produced in the Haryana, Punjab, Rajasthan, and Uttar Pradesh, the four agri-prominent north Indian states, which also generates an estimated 47 Million Tonnes of rice straw. This belt took large-scale cultivation of rice due to Government of India’s subsidy system, promotion and open-ended procurement of paddy securely backed by Food Corporation of India, which has its roots in the green revolution. Even though the government prohibits open field burning, including burning of rice straws, many farmers, however, continue to practice it. The pandemic has worsened the situation this year.

Despite an aggressive push from the government to move the cultivators away from stubble burning, the change appears to have not happened. The Central Sector Scheme on ‘Promotion of Agricultural Mechanization for In-Situ Management of Crop Residue in the States of Punjab, Haryana, Uttar Pradesh and NCT of Delhi’ promotes the agricultural machines and equipment for in-situ crop residue management such as Super Straw Management System (SMS) for Combine Harvesters, Happy Seeders, Hydraulically Reversible MB Plough, Paddy Straw Chopper, Mulcher, Rotary Slasher, Zero Till Seed Drill and Rotavators with 50% subsidy to the individual farmers and 80% subsidy for the establishment of Custom Hiring Centres of these machines. The State Governments during 2018-19 have supplied more than 56,290 machines to the individual farmers, and Custom Hiring Centres on subsidy for in-situ management of crop residue. During 2019-20, this scheme targeted to supply more than 46,578 machines. The Punjab Government established bio-mass power plants and has entered a contract with few corporates to produce Biogas, Bio CNG, and Bioethanol from paddy straw.

Source: NASA, FIRMS

As per our interactions with farmers, we believe below are the major reasons why farmers burn rice straw

While the efforts from the state government have been praiseworthy, the adoption of these practices by the farmers remains to be seen, and further push for implementation and suitable policy formulation with the focus on the below points should be made by the governments.

- Reduce stubble length further by the improvised harvester.

- To develop a solution to remove stubbles mechanically using tools that can be added to the existing tractors.

- Encourage farmers to create compost pits next to the farms to recycle the crop residue in the same plots. Thus, reduce the fertiliser input costs.

- The government can also look into similar incentives like MSP and government procurement to induce a shift in cropping patterns.

- A fallow land policy like in US Farm Policy or EU’s Common Ag Policy- farmers can set aside a portion of their holding every year for rotation with pulses/ fallow land and economic returns of providing such an incentive could be researched by relevant institutions.

Creating Value From Waste: Conclusion

Putting crop residue to economically beneficial end-uses offers a significant scope for increasing the farm productivity for a farmer. However, it is still perceived to have little value in the country because of its difficulty in the collection and lack of opportunities to use straw as an additional source of income. All the players in the ecosystem like government, farmers, corporates, etc, must collaborate to find ways to manage rice by-products, for optimal resource-use efficiency in farms in the most environmentally sustainable manner. Our policies may have to be reoriented by using solutions based on nature and explore the uses of different elements available within the ecosystem. Along with the farmers, the development of the value chain of the above products might also boost the rural economy by creating more rural jobs, entrepreneurs, and a new ecosystem. The need of the hour for all the stakeholders is to work together to beat air-pollution and hunger together. Thus, achieving the country’s aim of doubling farmers income by driving the secondary market of bi-products like paddy straw in this case.

Leave A Comment